Exploring Alternative Solutions for Indexable Tooling Efficiency

In the ever-evolving landscape of manufacturing, the quest for enhanced efficiency in Indexable Tooling has become increasingly critical. As industry reports indicate, tooling costs can represent up to 15% of total manufacturing expenditures, underscoring the need for alternative solutions that optimize performance while minimizing waste. A recent study revealed that adopting advanced indexable tooling strategies can improve machining efficiency by as much as 30%, enhancing productivity and reducing cycle times significantly. However, inherent challenges such as tool wear, productivity inconsistencies, and material compatibility are hurdles that firms must navigate. This blog will delve into these pressing issues surrounding Indexable Tooling and explore innovative approaches that can potentially transform traditional practices, paving the way for a more sustainable and cost-effective manufacturing future.

The Importance of High-Quality Coatings in Indexable Tooling Efficiency

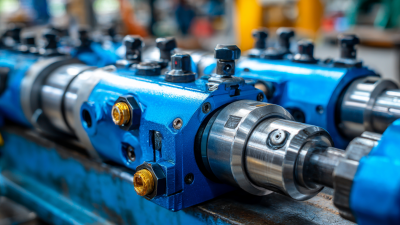

High-quality coatings play a crucial role in enhancing the efficiency of indexable tooling, especially in the face of challenging materials like high-temperature alloys and ultra-high strength steels. As industries such as aerospace, shipbuilding, and petrochemicals demand more from their materials, the need for advanced cutting tools becomes increasingly significant. Coatings such as carbide and diamond-enhanced layers not only improve wear resistance but also elevate thermal stability, allowing tools to maintain performance in extreme conditions.

Recent innovations in coating technology, particularly in the development of carbon-based coatings, have shown promising results. These coatings not only increase the tool life but also optimize the overall productivity of machining operations. The use of cutting-edge materials and advanced deposition techniques allows manufacturers to tailor coatings that meet specific application needs, thereby providing a competitive edge in precision machining tasks. As we explore alternative solutions for tooling efficiency, it is evident that investing in high-quality coatings will remain a key strategy for industries seeking to enhance their manufacturing capabilities.

Analyzing the Impact of Inserts Design on Tool Life and Performance

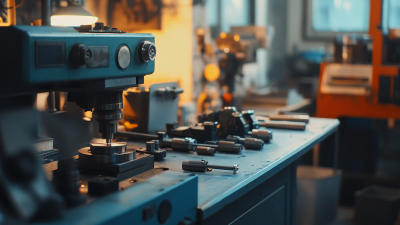

The design of cutting tool inserts plays a critical role in enhancing the efficiency and longevity of indexable tooling systems. As the global cutting tool insert market is projected to grow from USD 13.94 billion in 2024 to USD 22.93 billion by 2033, reflecting a compound annual growth rate (CAGR) of 5.7%, it is imperative to delve into how innovative insert designs impact both tool life and performance. Recent studies indicate that wiper inserts, which engage with workpieces differently compared to conventional inserts, can significantly reduce surface roughness and improve machining precision. This highlights the importance of insert geometry and material properties in optimizing cutting processes.

Moreover, advancements in additive manufacturing (AM) technology have paved the way for rapid production of customized mold inserts, contributing to better thermal management and cutting performance. Research surrounding different lubrication-cooling approaches during machining processes has also been gaining traction, showcasing how these methods can further enhance tool life while minimizing the environmental footprint. As industries increasingly adopt sophisticated analysis tools and techniques, the interplay between cutting tool insert design and overall tooling efficiency becomes ever more crucial in meeting the demands of modern manufacturing.

Comparative Study: Traditional vs. Alternative Tooling Solutions

In the manufacturing sector, the efficiency of indexable tooling solutions can greatly impact overall productivity and cost-effectiveness. Recent industry reports, such as the "2022 Global Cutting Tool Market Trends" by Grand View Research, indicate that the adoption of alternative tooling systems is on the rise, projected to witness a CAGR of 5.3% from 2023 to 2030. This growth is driven by advancements in materials and coatings that enhance the tool life and performance beyond what traditional steel or carbide tools can offer.

A comparative analysis reveals that alternative tooling solutions, such as polycrystalline diamond (PCD) and cubic boron nitride (CBN), often outperform traditional options in specific applications. According to a study by Market Research Future, while traditional cutting tools can provide satisfactory performance, alternative materials can achieve 30-50% longer tool life and up to 20% higher removal rates. This productivity boost can significantly affect machining costs, with manufacturers saving up to 15% on total operational expenses by switching to advanced tooling solutions. As the industry evolves, recognizing the benefits and potential of these alternatives becomes crucial for maintaining competitiveness in an increasingly demanding environment.

Unveiling the Role of Advanced Materials in Enhancing Tool Efficiency

As industries strive for greater efficiency in manufacturing processes, the role of advanced materials in enhancing tooling capabilities has come to the forefront. Traditional materials may not withstand the rigorous demands of today’s high-speed machining operations, leading to frequent tool failures and increased downtime. Advanced materials, such as ceramic composites and superalloys, are engineered to offer superior hardness, wear resistance, and thermal stability, paving the way for longer tool life and reduced operational costs.

Moreover, the integration of cutting-edge coatings on indexable tooling is revolutionizing efficiency. These coatings, often made from materials like titanium nitride and diamond-like carbon, improve friction characteristics and thermal conductivity, further enhancing the performance of the tools. By minimizing wear and heat generation during operation, they allow for faster machining speeds without compromising the quality of workpieces. As manufacturers explore these innovative material solutions, they find that not only does tool performance improve, but so does overall productivity—pushing the boundaries of what is possible in precision machining.

Real-World Case Studies: Efficiency Gains from Innovative Tooling Approaches

In the realm of manufacturing, enhancing tooling efficiency is critical for maintaining competitive advantage. Real-world case studies highlight a range of innovative tooling approaches that have led to significant efficiency gains. For instance, a recent study on the effectiveness of project-based learning (PBL) shows that engaging employees in collaborative knowledge-sharing can lead to better problem-solving capabilities—similar to how innovative tooling solutions foster greater productivity on the shop floor.

A growing body of evidence points to the impactful role of AI-powered technologies in reshaping tooling processes. For example, organizations that have integrated AI into their manufacturing operations report a 30% increase in production efficiency, illustrating the transformative potential of these advanced tools. Such approaches not only optimize workflows but also empower employees to take ownership of their tasks, thereby enhancing overall engagement.

**Tips:**

1. Consider implementing project-based learning strategies within your teams to facilitate knowledge sharing and problem-solving related to tooling processes.

2. Explore AI-driven tools that can streamline your operations—research indicates they can lead to a substantial boost in efficiency and innovation across industries.

3. Regularly assess your tooling methods against industry benchmarks to identify areas for improvement and adopt innovative solutions tailored to your operating environment.

Exploring Alternative Solutions for Indexable Tooling Efficiency - Real-World Case Studies: Efficiency Gains from Innovative Tooling Approaches

| Case Study | Tooling Solution | Efficiency Gain (%) | Cycle Time Reduction (mins) | Material Type |

|---|---|---|---|---|

| Case Study 1 | High-Performance Inserts | 25% | 2.5 | Aluminum |

| Case Study 2 | Ceramic-Coated Tools | 30% | 3.0 | Stainless Steel |

| Case Study 3 | Specialized Inserts for Hard Materials | 20% | 1.8 | Titanium Alloys |

| Case Study 4 | Advanced Tool Geometries | 15% | 1.2 | Carbon Steel |

| Case Study 5 | Multi-Functional Tooling Systems | 40% | 4.5 | Alloy Steels |

Related Posts

-

Global Market Trends for Indexable Milling Tools by 2025

-

High-Quality Pneumatic Tools from China: Your Trusted Global Manufacturing Partner

-

Global Buyers Discover the Excellence of Chinese Manufacturing with Best Tools Shop

-

Mastering Live Tool Repair Techniques for Enhanced Machine Performance

-

Optimizing Efficiency with Innovative Milling Cutter Solutions

-

Comparative Analysis of Top Indexable Tool Repair Services for Optimal Efficiency