How to Choose the Right Machine Shop Tools for Your Projects

In the ever-evolving landscape of manufacturing, selecting the right machine shop tools is crucial for optimizing efficiency and precision in your projects. According to a report by IBISWorld, the machine shop industry in the United States alone generates over $40 billion in revenue annually, highlighting the importance of high-quality tools in maintaining competitiveness. A strategic approach to tool selection not only enhances productivity but also reduces downtime and operational costs. With advancements in technology and varying project requirements, understanding the specific functions and capabilities of different machine shop tools becomes essential.

Whether you're embarking on a small-scale project or a large industrial operation, this guide will equip you with the knowledge to make informed decisions that align with your technical needs and business goals.

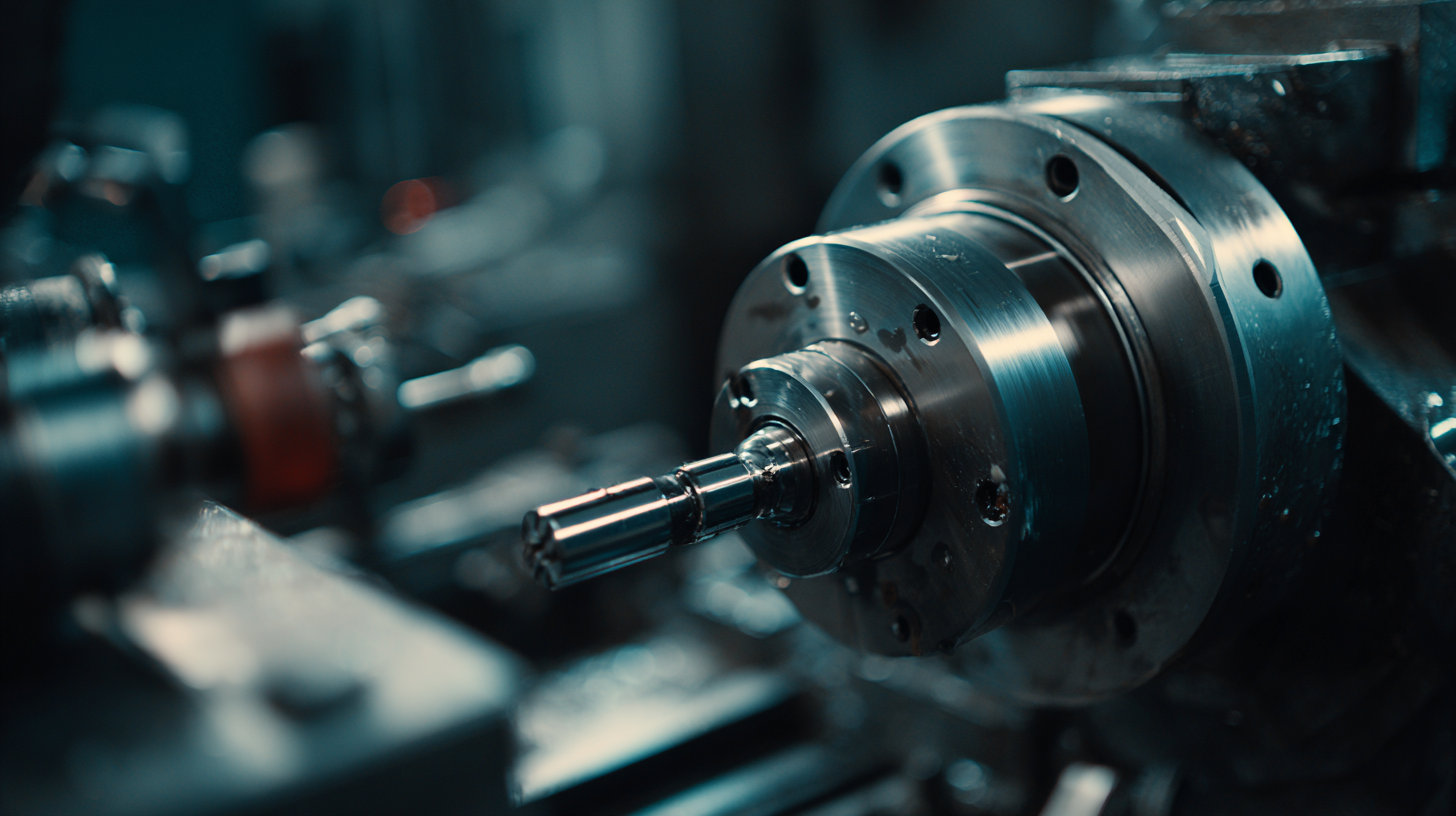

Understanding the Different Types of Machine Shop Tools Available

When it comes to choosing the right machine shop tools for your projects, it's essential to understand the various types of tools available in today's market. The global CNC machine market, for instance, is projected to experience significant growth from $101.22 billion in 2025 to an estimated $195.59 billion by 2032, driven by a CAGR of 9.9%. Such growth highlights the increasing demand for precision tools that enhance productivity and efficiency in machining processes.

In addition to CNC machines, there are various other tools that play a critical role in machining operations. Cutting tools, for example, are subjected to wear as they engage with materials, which can impact their effectiveness. A systematic literature review on tool wear mechanisms reveals the underlying physics that govern the wear process, providing valuable insights for selecting the appropriate cutting tools based on the materials being worked on. Furthermore, advancements in tooling management software are transforming how manufacturers oversee their tool inventory and usage, connecting to the cloud and enabling management via mobile devices, which streamlines operations and minimizes downtime.

Understanding these different types of machine shop tools, along with their specific applications and management solutions, can empower professionals to make informed decisions that enhance the efficiency and success of their projects.

Evaluating Your Project Requirements for Tool Selection

When it comes to selecting the right machine shop tools for your projects, the first step is to thoroughly evaluate your project requirements. Understanding the specifics of your project—such as material type, size, complexity, and the desired finish—will significantly influence your tool selection process. For instance, if you are working with hard metals, you might require tools made from high-speed steel or carbide, whereas softer materials could be accommodated with more basic tool options.

Additionally, consider the precision and detail needed in your project. Projects that demand high accuracy will benefit from tools designed for fine machining, such as CNC mills or lathes, while less intricate tasks might only need hand tools. Furthermore, think about the volume of production; for high-volume projects, investing in automated tools can save both time and costs. By carefully assessing these factors, you can make an informed decision that maximizes efficiency and effectiveness in your machine shop.

How to Choose the Right Machine Shop Tools for Your Projects

| Tool Type | Project Suitability | Material Compatibility | Price Range | Usage Skill Level |

|---|---|---|---|---|

| Lathe Machine | Ideal for turning operations | Metals, plastics | $5,000 - $20,000 | Intermediate to Advanced |

| Milling Machine | Perfect for flat and complex surfaces | Metals, wood, composites | $3,000 - $15,000 | Intermediate to Advanced |

| Drill Press | Best for precise drilling | Wood, metals | $200 - $2,500 | Beginner to Advanced |

| Bandsaw | Useful for cutting curves and irregular shapes | Wood, metals | $200 - $5,000 | Beginner to Intermediate |

| CNC Router | Ideal for automated cutting | Wood, plastics | $2,000 - $30,000 | Advanced |

Key Factors to Consider When Choosing Machine Shop Tools

When selecting the right machine shop tools for your projects, there are several key factors to consider that can significantly impact your workflow and the quality of your output. First and foremost, evaluate the type of projects you anticipate tackling. Different types of tasks—be it machining, fabrication, or assembly—require specific tools designed to handle the unique demands of each process. For instance, if precision is a top priority, investing in high-quality milling machines and lathes would be essential.

Additionally, consider the compatibility of the tools with your existing machinery and workspace. Space constraints may dictate whether you choose standalone machines or integrated solutions. Furthermore, tool durability and ease of maintenance should also weigh heavily in your decision-making process. High-performance tools that are easy to service will save you time and money in the long run, while also minimizing downtime during critical project phases. Ultimately, aligning the selection of your tools with your project requirements and operational needs can set the foundation for successful outcomes in any machining endeavor.

Essential Safety Practices When Using Machine Shop Tools

When operating in a machine shop, prioritizing safety is paramount. Essential safety practices begin with wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and steel-toed boots. These items protect against common hazards, including flying debris and heavy materials. Additionally, hearing protection may be necessary in environments with loud machinery to prevent long-term hearing damage. Educating oneself about the specific risks associated with each tool is critical, ensuring that users understand both the equipment and their own limits.

Beyond personal gear, maintaining a clean and organized workspace is crucial in promoting safety. Clutter can lead to accidents, so it's important to regularly tidy up and ensure that tools are stored properly after use. Moreover, familiarizing oneself with emergency procedures and the location of first aid kits or eyewash stations can save valuable time in the event of an incident. Finally, proper training on each tool not only enhances efficiency but also minimizes the risk of injury, creating a more secure environment for all.

Budgeting for Quality: Investing in Durable Machine Shop Tools

When budgeting for machine shop tools, it’s crucial to recognize that investing in quality equipment can yield long-term advantages for your projects. Research indicates that high-quality tools can last up to 300% longer than their cheaper counterparts, ultimately leading to reduced maintenance costs and increased productivity. This durability is especially vital given the significant annual spending in related industries; for instance, major utilities have increased their expenditure on infrastructure by 12% over the past two decades. Such financial trends underline the importance of allocating budget towards reliable tools that enhance efficiency and performance.

Additionally, the current focus on sustainable investments reflects a broader shift towards prioritizing quality over quantity. Just as the U.S. military budget emphasizes securing high-quality capabilities, machine shop operators should replicate this strategy by selecting tools that meet rigorous standards. Reports suggest that businesses experiencing growth are the ones that prioritize quality investments, allowing them to adapt rapidly to changes while maintaining operational effectiveness. By finding the right balance between cost and quality, machine shop owners can not only safeguard their financial resources but also ensure the success of their projects in an increasingly competitive market.

Related Posts

-

Unlocking Precision Engineering with Tailor Made Carbide Tooling Solutions

-

Exploring the Future of Tool Holders at the 137th Canton Fair: Innovations and Opportunities Ahead

-

Maximizing Efficiency: The Benefits of Best Indexable Tool Repair for Your Business

-

Unlocking the Potential of Carbide Cutters for Precision Manufacturing Needs

-

Chinese Manufacturing Growth Surges Amidst US China Tariff Challenges with Best Tool Services

-

Key Factors in Selecting Reliable Manufacturers for Indexable Tool Repair Services