Mastering Custom Parts Manufacturing Techniques with Data Driven Insights for Optimal Production Efficiency

In the dynamic landscape of Custom Parts Manufacturing, the integration of data-driven insights is becoming a game-changer for optimizing production efficiency. As manufacturers strive to meet escalating demands for precision and versatility, traditional methods are often plagued by inefficiencies and inconsistencies. This blog aims to explore the common problems associated with Custom Parts Manufacturing, such as productivity bottlenecks and material waste, while highlighting how leveraging advanced data analytics can streamline processes and enhance decision-making. By addressing these challenges head-on, businesses can not only improve their operational performance but also foster innovation and responsiveness in a competitive market.

In the dynamic landscape of Custom Parts Manufacturing, the integration of data-driven insights is becoming a game-changer for optimizing production efficiency. As manufacturers strive to meet escalating demands for precision and versatility, traditional methods are often plagued by inefficiencies and inconsistencies. This blog aims to explore the common problems associated with Custom Parts Manufacturing, such as productivity bottlenecks and material waste, while highlighting how leveraging advanced data analytics can streamline processes and enhance decision-making. By addressing these challenges head-on, businesses can not only improve their operational performance but also foster innovation and responsiveness in a competitive market.

Join us as we delve into effective techniques and strategies that turn data into actionable intelligence, paving the way for a new era of efficiency in custom manufacturing.

Understanding the Importance of Custom Parts in Modern Manufacturing

In modern manufacturing, custom parts play a pivotal role, driving innovation and efficiency across various industries. The global Auto Parts Manufacturing market, valued at approximately USD 701.57 billion in 2024, underscores the rising demand for tailored components. As manufacturers strive to enhance their offerings, understanding the specific needs of aftermarket sales becomes essential. A well-integrated aftermarket strategy not only bolsters customer satisfaction but also contributes significantly to revenue growth, creating a feedback loop that informs future production decisions.

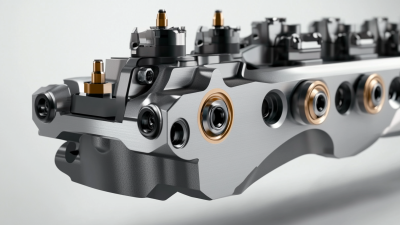

The advent of advanced manufacturing techniques, such as wire and arc additive manufacturing and 3D printing, further enriches the landscape of custom parts. With these technologies, manufacturers can achieve remarkable precision and flexibility in producing complex designs that were once thought impossible. However, challenges remain, particularly in managing quality and ensuring that production processes meet industry standards. By harnessing data-driven insights, manufacturers can navigate these challenges effectively, optimizing production efficiency while maintaining the integrity and accuracy of their custom parts. This alignment of technology with strategic foresight is crucial for success in the increasingly competitive manufacturing arena.

Mastering Custom Parts Manufacturing Techniques with Data Driven Insights for Optimal Production Efficiency

| Dimension | Value |

|---|---|

| Process Type | Additive Manufacturing |

| Lead Time (days) | 5 |

| Material Type | Aluminum |

| Cost per Part ($) | 15.00 |

| Production Efficiency (%) | 90 |

| Scrap Rate (%) | 2 |

| Custom Part Applications | Aerospace, Automotive, Medical |

| Average Order Size (units) | 100 |

Leveraging Data Analytics for Streamlined Production Processes

In today’s fast-paced manufacturing landscape, leveraging data analytics has become essential for streamlining production processes. By harnessing the power of data, manufacturers can identify inefficiencies, optimize workflows, and enhance the quality of custom parts. Advanced analytics tools enable companies to gather and analyze vast amounts of production data in real-time, allowing them to make informed decisions that drive productivity and reduce waste.

Implementing data-driven insights not only improves operational efficiency but also fosters a culture of continuous improvement. For instance, predictive maintenance can be initiated through data analytics, helping manufacturers anticipate equipment failures before they occur. This approach minimizes downtime and maximizes output. Furthermore, analyzing production trends and workflows allows businesses to allocate resources more effectively, ensuring that the right materials and labor are available when needed. By adopting these strategies, manufacturers can achieve a seamless production process that not only meets but exceeds market demands, ultimately leading to enhanced profitability and customer satisfaction.

Exploring Innovative Techniques in Custom Parts Manufacturing

In today's fast-paced manufacturing landscape, custom parts manufacturers are increasingly leveraging innovative techniques to enhance production efficiency. According to a report by McKinsey & Company, companies that adopt data-driven approaches to manufacturing can boost their productivity by as much as 30%. This efficiency is primarily achieved through the implementation of advanced technologies such as additive manufacturing, robotic process automation, and the Internet of Things (IoT). These technologies not only streamline operations but also reduce waste, allowing for quicker turnaround times and a more agile manufacturing process.

Moreover, the Global Custom Parts Manufacturing Market is projected to reach USD 156.79 billion by 2028, with a compound annual growth rate (CAGR) of 7.3% from 2021 to 2028, as indicated in a report by Fortune Business Insights. Innovative techniques, such as micro-manufacturing and smart materials, are becoming essential for staying competitive in this evolving market. By harnessing data-driven insights, manufacturers can optimize their designs and processes, resulting in superior product quality and flexibility to meet unique customer demands. This shift towards innovation is vital for any manufacturer looking to adapt and thrive in an increasingly complex and demanding industry environment.

Improving Quality Control through Data-Driven Insights

Data-driven insights have revolutionized quality control in custom parts manufacturing, enabling companies to achieve unprecedented levels of precision and efficiency. According to a report by McKinsey & Company, businesses leveraging analytics for quality control can reduce defects by up to 30%. By implementing predictive analytics, manufacturers can foresee potential quality issues and take corrective actions before they escalate, ensuring that only top-grade products reach the market.

To enhance your quality control processes, consider these tips: First, invest in advanced data collection technologies, such as IoT devices, to gather real-time data on manufacturing performance. This will help you identify patterns and pinpoint quality issues during production. Second, establish a feedback loop where data insights are shared across teams; this collaborative approach can foster innovation and continual improvement in quality standards.

Moreover, integrating machine learning algorithms can optimize manufacturing workflows. According to a recent report by Gartner, organizations using AI in their quality control processes have seen a 20% increase in operational efficiency. By focusing on data-driven strategies, manufacturers can not only improve their quality control measures but also drive overall production efficiency, leading to enhanced customer satisfaction and loyalty.

Maximizing Cost Efficiency with Predictive Manufacturing Strategies

In the realm of custom parts manufacturing, maximizing cost efficiency is crucial for maintaining a competitive edge. One effective strategy is to implement predictive manufacturing techniques that leverage data analytics to forecast demand and optimize production schedules. By analyzing historical data and trends, manufacturers can accurately predict which parts will be needed and when, effectively reducing waste and minimizing excess inventory costs.

Tip 1: Utilize advanced software tools to centralize data collection and analysis. This allows for real-time insights that can drive quicker decision-making and align production with market demands.

Adopting these predictive strategies not only streamlines operations but also enhances performance metrics. Another recommendation is to create a feedback loop between production and sales departments. This collaboration ensures that manufacturing activities are directly informed by customer requirements, enabling a more agile response to market fluctuations.

Tip 2: Invest in staff training for data interpretation skills. Empowering your team to understand data insights can significantly enhance the effectiveness of predictive strategies and lead to smarter production choices.

Related Posts

-

Innovative Examples of Custom Parts Manufacturing in Various Industries

-

Chinese Manufacturing Growth Surges Amidst US China Tariff Challenges with Best Tool Services

-

Discover the Future of Best Indexable Tooling in 2023

-

Maximize Performance and Reduce Maintenance Costs with 7 Essential Tips for Indexable Milling

-

Key Factors in Selecting Reliable Manufacturers for Indexable Tool Repair Services

-

Unlocking Global Trade: The Impact of Certification Standards on Indexable Tooling Procurement