7 Innovative Approaches to Custom Parts Manufacturing for Your Business Success

In today's competitive landscape, Custom Parts Manufacturing has become a cornerstone for businesses seeking to innovate and thrive. As industries evolve and customer demands shift, the traditional methods of production are often no longer sufficient to meet the diverse needs of the market. This blog explores seven innovative approaches that not only enhance the efficiency and quality of custom parts but also contribute to the overall success of your business. From advanced technologies like 3D printing to agile manufacturing techniques, each method offers unique benefits that can help streamline operations, reduce costs, and foster creativity in product design. By embracing these strategies, companies can position themselves at the forefront of their industries, adapt to changing trends, and ultimately drive growth. Join us as we delve into these transformative approaches that are sure to redefine your custom parts manufacturing processes.

Leveraging 3D Printing Technology for Custom Parts Production

3D printing technology is revolutionizing the custom parts manufacturing landscape, offering innovative solutions that significantly enhance production efficiency and design flexibility. Aerospace companies are at the forefront of this transformation, utilizing additive manufacturing to create lighter components that not only reduce fuel consumption but also allow for more intricate designs that were previously impossible with traditional methods. This shift not only accelerates the time-to-market but also fosters a new wave of creativity in aerospace engineering.

In the automotive sector, the ability to 3D print parts is reshaping how vehicles are produced and customized. From rapid prototyping to the production of precision components, automotive manufacturers are increasingly leveraging this technology to meet the growing demand for personalized and complex parts. As exemplified by advancements in ultra-luxury vehicles, the integration of 3D printing into mainstream production lines signifies a trend toward more innovative vehicle design and manufacturing processes. As this technology continues to evolve, it promises to drive significant advancements across various industries, making custom fabrication more accessible and cost-effective than ever before.

Implementing AI-Driven Design Tools in Manufacturing Processes

The integration of AI-driven design tools in custom parts manufacturing is revolutionizing the industry, streamlining processes, and enhancing product quality. According to a report by MarketsandMarkets, the global AI in manufacturing market is projected to reach $16.7 billion by 2026, growing at a CAGR of 49.5% from 2021. This surge indicates a growing recognition of AI’s potential to optimize design processes, reduce time-to-market, and facilitate greater customization at lower costs.

AI-powered design tools leverage advanced algorithms to analyze vast datasets, allowing manufacturers to create innovative designs quickly and efficiently. For example, generative design software can produce multiple design alternatives based on predefined specifications and constraints, enabling engineers to select the most effective solutions. A study by Deloitte also highlighted that 83% of organizations utilizing AI in their design processes reported improved product development times. With AI tools ensuring high precision and reducing human error, manufacturers can achieve an unprecedented level of efficiency, ultimately setting the stage for increased competitiveness in the market.

Innovative Approaches to Custom Parts Manufacturing Using AI-Driven Design Tools

This chart illustrates the percentage of companies implementing innovative approaches to custom parts manufacturing over the last five years. The data showcases the increasing adoption of AI-driven design tools in the manufacturing process, highlighting the shift towards more efficient and precise manufacturing strategies.

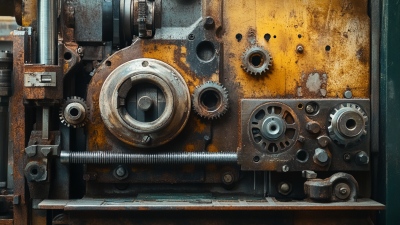

Exploring the Benefits of Modular Manufacturing Systems

In today's competitive landscape, modular manufacturing systems are revolutionizing the way businesses approach custom parts production. These systems break down complex manufacturing processes into smaller, interchangeable units, allowing for greater flexibility and efficiency. By adopting a modular approach, companies can quickly adapt to changing market demands and streamline their production lines.

Tip: Start by assessing your current manufacturing processes to identify areas where modular systems could offer improvements. Look for components or processes that can be standardized and combined into modular units, enhancing both speed and adaptability.

Moreover, modular manufacturing systems enable easier collaboration within teams and between suppliers. With clearer boundaries and defined roles, communication improves, fostering an environment where innovation thrives. By leveraging modularity, businesses can not only optimize operations but also enhance product quality and reduce lead times.

Tip: Invest in training your workforce to effectively utilize modular systems. Providing comprehensive training ensures that employees can maximize the benefits of modular manufacturing, leading to increased productivity and job satisfaction.

Utilizing Advanced Materials for Enhanced Part Performance

The utilization of advanced materials is crucial for enhancing part performance in custom parts manufacturing. Recent innovations have focused on the integration of cutting-edge materials, such as graphene-based electrodes and biomaterials for medical applications, which significantly improve functionality and efficiency. For instance, the new developments in graphene for supercapacitors emphasize its potential in creating high-performance energy storage solutions, demonstrating the tangible benefits of sophisticated material choices.

Furthermore, advancements in material extrusion techniques, particularly in biomedical applications, highlight how tailored materials can lead to superior outcomes. Techniques like Fused Filament Fabrication (FFF) and Direct Ink Writing (DIW) are becoming increasingly important in producing customized components that meet specific engineering challenges. These methods, when combined with novel materials such as bioceramics, not only enhance mechanical properties but also foster the development of multifunctional applications, including scaffolds for bone tissue engineering. As industries strive for success through innovation, the focus on advanced materials remains a driving force in achieving superior part performance.

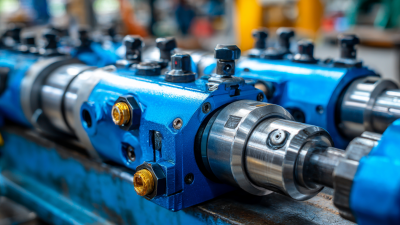

Integrating IoT for Real-Time Monitoring and Quality Control

The integration of the Internet of Things (IoT) in custom parts manufacturing has transformed the way businesses approach real-time monitoring and quality control. By leveraging IoT devices and sensors, manufacturers can track the performance of machinery and assess the conditions under which components are produced. This enables immediate detection of anomalies, ensuring that any potential defects are addressed before they escalate into larger production issues. As a result, companies can maintain high standards of quality while optimizing their operational efficiency.

Moreover, IoT technology facilitates the collection of vast amounts of data that can be analyzed to gain insights into production processes. By harnessing this data, manufacturers can implement predictive maintenance strategies that minimize downtime and extend the lifespan of equipment. This proactive approach not only boosts productivity but also reduces costs associated with repairs and waste. The ability to monitor processes in real-time empowers businesses to make informed decisions, ultimately leading to higher customer satisfaction and better market competitiveness.

Related Posts

-

Maximizing Your Investment in Machine Shop Tools Through Effective Maintenance Strategies

-

Innovative Solutions for Enhancing Efficiency with Best Custom Carbide Tooling

-

Maximizing Efficiency: The Benefits of Best Indexable Tool Repair for Your Business

-

High-Quality Pneumatic Tools from China: Your Trusted Global Manufacturing Partner

-

Revolutionizing Global Procurement with Indexable Milling Cutters at the 137th Canton Fair

-

Challenges Faced in Achieving Optimal Results with Best Indexable Milling Techniques