The Ultimate Guide to Choosing the Right Machine Shop Services for Your Business Needs

In today's competitive landscape, the importance of selecting the right Machine Shop Services cannot be overstated. According to a recent report by IBISWorld, the machine shop industry is projected to reach a revenue of $46 billion by 2024, driven by a surge in demand across manufacturing sectors, including aerospace, automotive, and industrial machinery. As businesses increasingly rely on precision engineering and custom fabrication, understanding the nuances of available services becomes crucial for operational success. This ultimate guide aims to illuminate the various factors to consider when choosing machine shop services, emphasizing how the right partnerships can enhance productivity, reduce costs, and ultimately contribute to your company's growth.

Identifying Your Specific Machining Needs for Optimal Results

When it comes to selecting the right machine shop services, identifying your specific machining needs is crucial for achieving optimal results. Every business has unique requirements based on their industry, product specifications, and production volumes. Start by determining the materials you will be working with, as different materials may require specialized machining techniques. For instance, working with metals like aluminum or steel can differ significantly in terms of tooling and machinery used. Specializing in materials can help you narrow down potential machine shops that have experience with your specific needs.

Additionally, consider the complexity of your designs and the precision required. High-tolerance parts may necessitate CNC machining, while simpler components might be suited for traditional methods. Assess your production scale—whether you're producing prototypes or a high volume of parts—since this will impact the choice of machining services as well. By clearly articulating your project requirements, you can better evaluate the capabilities of various machine shops, ultimately ensuring that you partner with one that aligns perfectly with your goals and enhances your production efficiency.

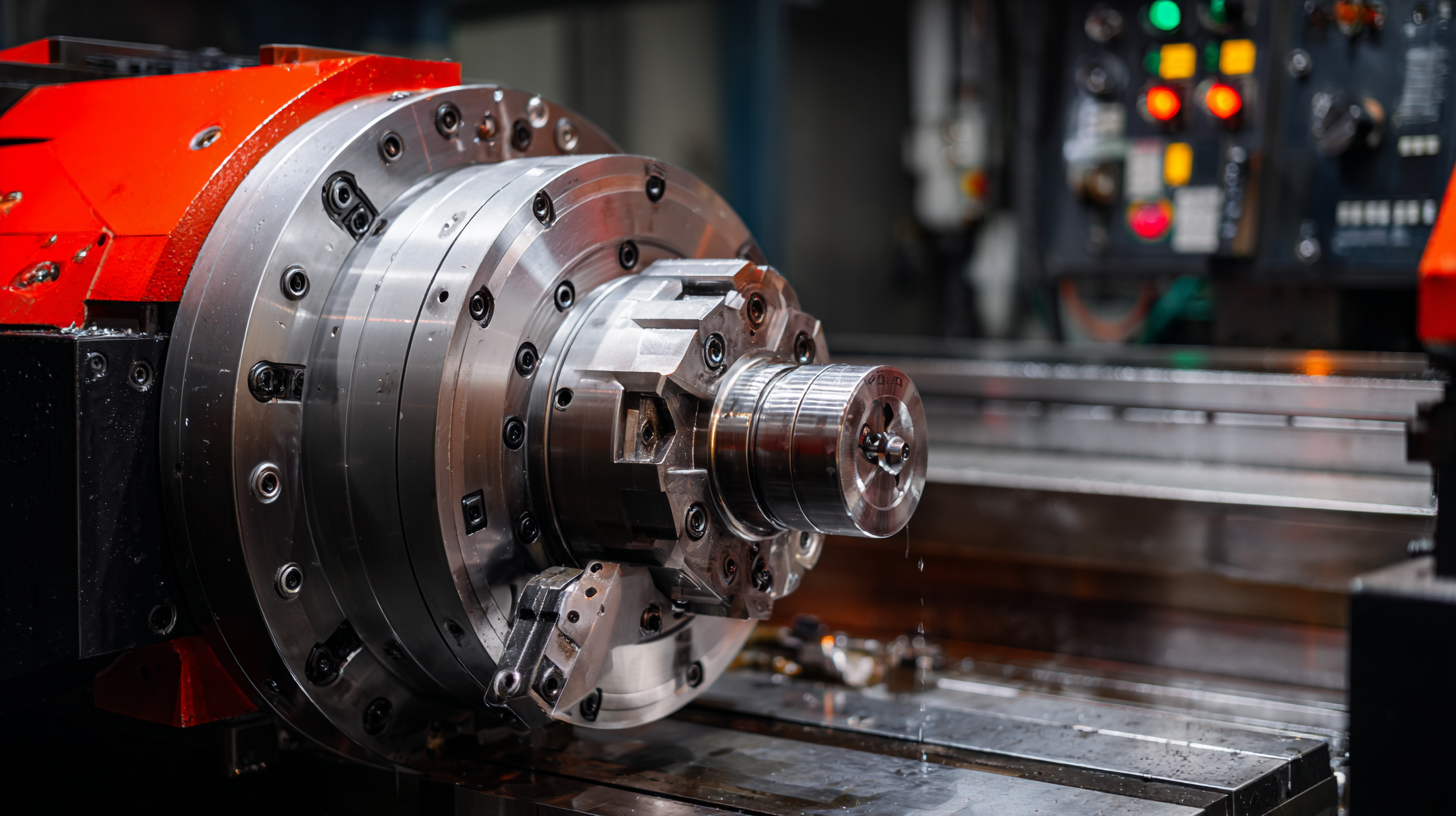

Evaluating Machine Shop Capabilities: What to Look For

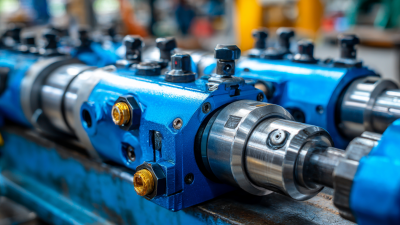

When evaluating machine shop capabilities for your business, it’s crucial to focus on key aspects that distinguish high-quality services. First, assess the range of services offered. A versatile machine shop should provide

CNC machining, metal fabrication, welding, and assembly services. This flexibility ensures that they can handle various projects and adapt to your unique specifications.

Tip: Always inquire about the shop's expertise with different materials, such as aluminum, steel, or plastic, to ensure they can accommodate your specific needs.

Tip: Request samples of previous work or visit the shop to witness their operations firsthand, which can provide insight into their process capabilities and quality control measures.

Lastly, don't overlook the importance of customer service and communication. A machine shop that values transparency and responsiveness can help ensure a smoother collaboration and project success.

Tip: Establish clear communication channels from the start to avoid misunderstandings and ensure your requirements are met effectively.

Understanding Different Machining Processes and Their Applications

When selecting machine shop services, it’s crucial to understand the various machining processes available and their specific applications. According to a report by Grand View Research, the global CNC machining market size was valued at approximately $68.42 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028. This growth underscores the importance of choosing the right process tailored to your business needs, whether that involves CNC turning, milling, or electrical discharge machining (EDM).

Each machining process offers unique benefits and applications. For instance, CNC milling is well-suited for creating complex shapes and high-precision components in industries ranging from aerospace to medical device manufacturing. On the other hand, turning processes excel in producing cylindrical parts and are essential in the automotive sector. A report from Market Research Future highlights that the demand for precision-engineered components is escalating, further driving the relevance of advanced machining techniques. Understanding these processes will enable businesses to make informed decisions that enhance productivity and product quality.

The Ultimate Guide to Choosing the Right Machine Shop Services for Your Business Needs

This bar chart illustrates the number of businesses utilizing different machining processes. Each service has varying levels of adoption, with CNC Machining being the most popular among businesses seeking machine shop services.

Assessing Quality Standards and Certifications in Machine Shops

When selecting a machine shop for your business, assessing quality standards and certifications is crucial. A reputable machine shop should hold industry-recognized certifications such as ISO 9001, which ensures that processes are consistently aimed at quality and customer satisfaction. Certifications not only signify compliance with international standards but also reflect a commitment to continuous improvement and operational excellence. It's essential to verify these credentials, as they can greatly influence the reliability of the services provided.

In addition to certifications, understanding the quality control measures employed by the machine shop is vital. Look for shops that implement rigorous inspection processes and utilize advanced quality assurance tools. This could include statistical process control (SPC) and non-destructive testing (NDT) techniques. A shop that prioritizes these methodologies demonstrates a proactive approach to preventing defects and ensuring that the final products meet your specific requirements. Engaging with machine shops that align with your quality standards can lead to partnerships that enhance your overall production efficiency and reliability.

The Ultimate Guide to Choosing the Right Machine Shop Services for Your Business Needs

| Service Type | Quality Standard | Certification | Lead Time (Days) | Cost Estimate ($) |

|---|---|---|---|---|

| CNC Machining | ISO 9001 | AS9100 | 15 | 2500 |

| Welding Services | AWS D1.1 | ISO 3834 | 10 | 3000 |

| Sheet Metal Fabrication | ISO 9001 | NQA1 | 20 | 1500 |

| Injection Molding | ISO 13485 | TS 16949 | 25 | 4000 |

| 3D Printing | ASTM F2792 | ISO 3033 | 5 | 1000 |

Budgeting and Cost Considerations for Machine Shop Services

When choosing machine shop services, budgeting and cost considerations are paramount for businesses looking to optimize their operations. Understanding production costs is vital, as these represent the expenses directly tied to manufacturing goods or providing services. It’s essential to categorize these costs accurately, taking into account labor, materials, and overhead. As organizations face the challenge of doing more with fewer resources, strategic financial planning becomes crucial.

Effective cost optimization can significantly improve your machine shop services. By prioritizing targeted investments in technology and data, businesses can enhance their manufacturing processes while addressing workforce challenges. Additionally, considering multi-cloud strategies can offer flexibility and reduce the risk of vendor lock-in, ultimately contributing to more efficient budgeting. As manufacturers continue to navigate a competitive landscape, adopting these cost-effective practices will not only streamline operations but also safeguard against market fluctuations.

Related Posts

-

7 Innovative Approaches to Custom Parts Manufacturing for Your Business Success

-

Maximizing Efficiency: The Benefits of Best Indexable Tool Repair for Your Business

-

Revolutionizing Global Procurement with Indexable Milling Cutters at the 137th Canton Fair

-

Ultimate Checklist for Sourcing the Best Carbide Tools Worldwide

-

High-Quality Pneumatic Tools from China: Your Trusted Global Manufacturing Partner

-

Unlocking the Potential of Carbide Cutters for Precision Manufacturing Needs